Make it possible: process improvement, calculation per unit production and equipment maintenance

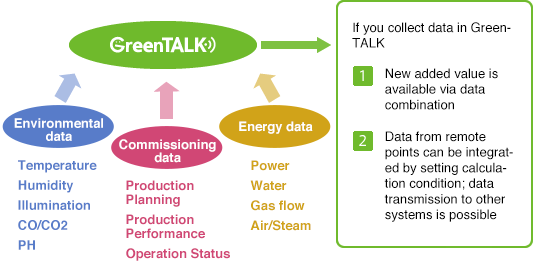

Visual control solution for factories makes it possible to visualize the entire factories not only by collecting energy data but also a variety of data including temperature, humidity, CO2, equipment information, operation information, etc.

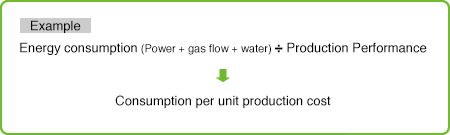

New added values including energy consumption per unit production cost based on production performance data and energy consumption data are available; various kinds of data of the whole factory can be utilized effectively.

System Configuration

Implementation Results

Result 1: New added value is available by data combination

New added value would be provided by integrating data from different remote points handled and controlled respectively.

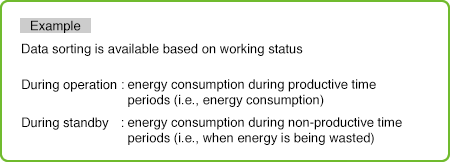

Result 2: Grasp various data with a single system

Generally, data from different remote points should be handled and controlled respectively and needed to be referred one by one.

GreenTALK enables to grasp every data from each system, to compare every data on the same monitor, and to make tendencies visible on the graphs, etc. Data collection and data centralization are extremely effective methods for analysis.

GreenTALK achieves your goals

- We cannot overview power consumption data and other different consumption data on one monitor

- We cannot analyze every data from different systems